ELECTRODE HANDLING

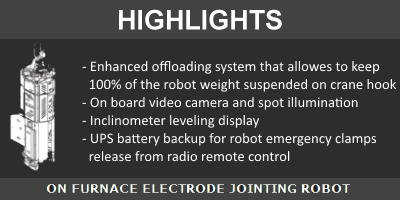

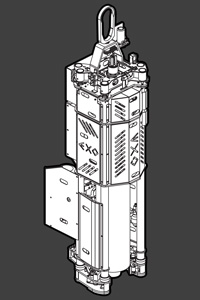

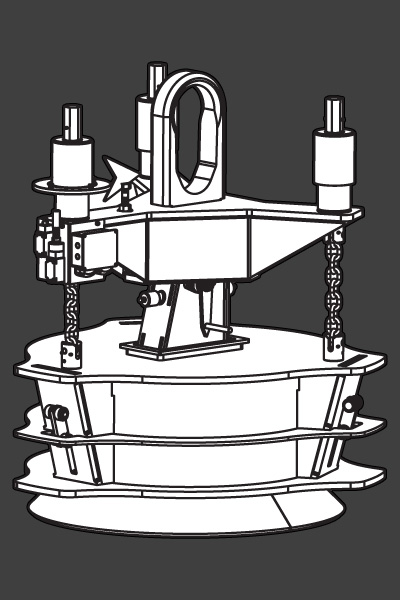

ON FURNACE ELECTRODE JOINTING ROBOT

• Designed for Electric Arc or Ladle Refining Furnaces, adds electrodes “on furnace” to eliminate off furnace oxidation.

• Operated from the melt shop floor, reduces accident exposure compared to manual on furnace addition or electrode column exchange.

• Hydraulically torques electrodes (2 and 4 tpi) to manufacturers exacting specifications.

• Quick (2-3 minute power off) electrode additions, or live additions.

• Prevents cross threading of electrodes.

• Holds the electrode column while slipping electrodes.

• Radio controlled for freedom of operators.

• PLC controlled to prevent human error.

• HMI provides complete system control and diagnostics.

• Machine has manual reverse to allow removal of previously joined electrode segments.

• Designed for easy crane pickup and rapid access to the furnace column it is compatible with all electrode holders.

• Machine has motorized rotation for control of approach to electrode holders and hydraulic suspension cylinders to prevent offloading the full weight(**) of the machine on the arms.

• Machine works with electrode socket covers and onboard air compressor.

• Onboard hydraulic self contained system.

• Onboard video camera and spot illumination.

• Inclinometer leveling display.

• UPS battery backup for robot emergency clamps release from radio remote control.

(**) The enhanced offloading system allowes to keep 100% of the robot weight suspended on crane hook.

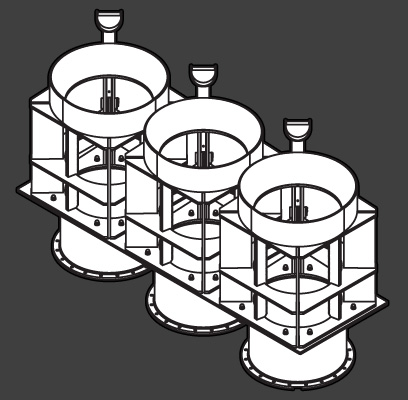

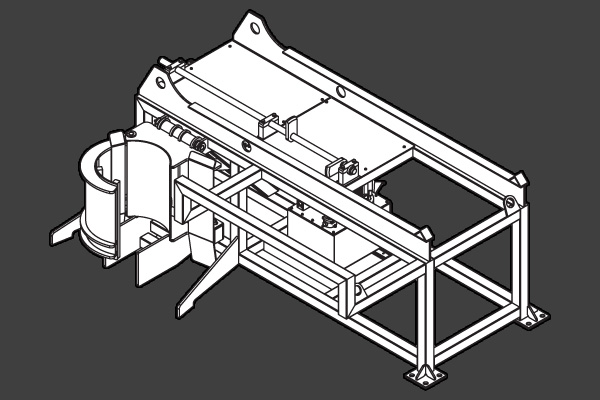

ELECTRODE TILTING & STORAGE STATION

- Designed for Electric Arc or Ladle Refining Furnaces.

- Holds 1-6 electrodes horizontally.

- Positions the electrodes vertically for loading into the Jointing Robot.

- Prevents damages to the electrode nipple.

- Safely clamps and tilts electrodes from a remote portable control box.

- Onboard hydraulic self contained system.

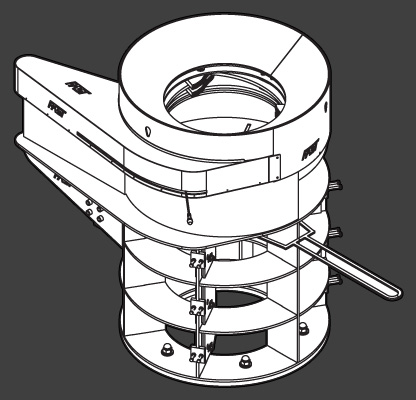

ELECTRODE TORQUE STATION

- Designed for Electric Arc or Ladle Refining Furnaces.

- Hydraulically torques electrodes (2 and 4 tpi) to manufacturers exacting specifications.

- PLC controlled for semi-automatic operation.

- PLC control for complete system control and diagnostics.

- Machine has manual reverse to allow removal of previously joined electrode segments.

- Onboard hydraulic self contained system.

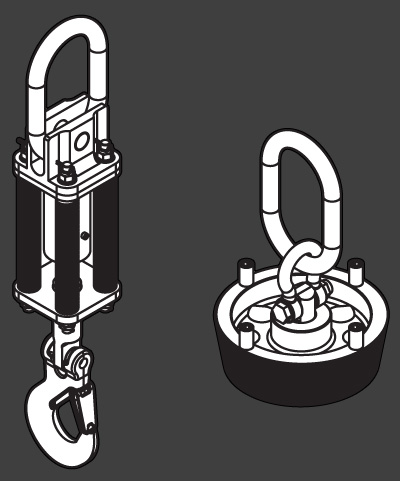

ELECTRODE COLUMN LIFTING

- Designed for Electric Arc or Ladle Refining Furnaces.

- Operated from the melt shop floor, reduces accident exposure compared to lifting plug.

- Three point (120 degree) contact pads reduces crushing stress to electrode socket.

- Provided with safetylocking features to prevent inadvertent unclamping.

- Mechanic, pneumatic or electric operation.

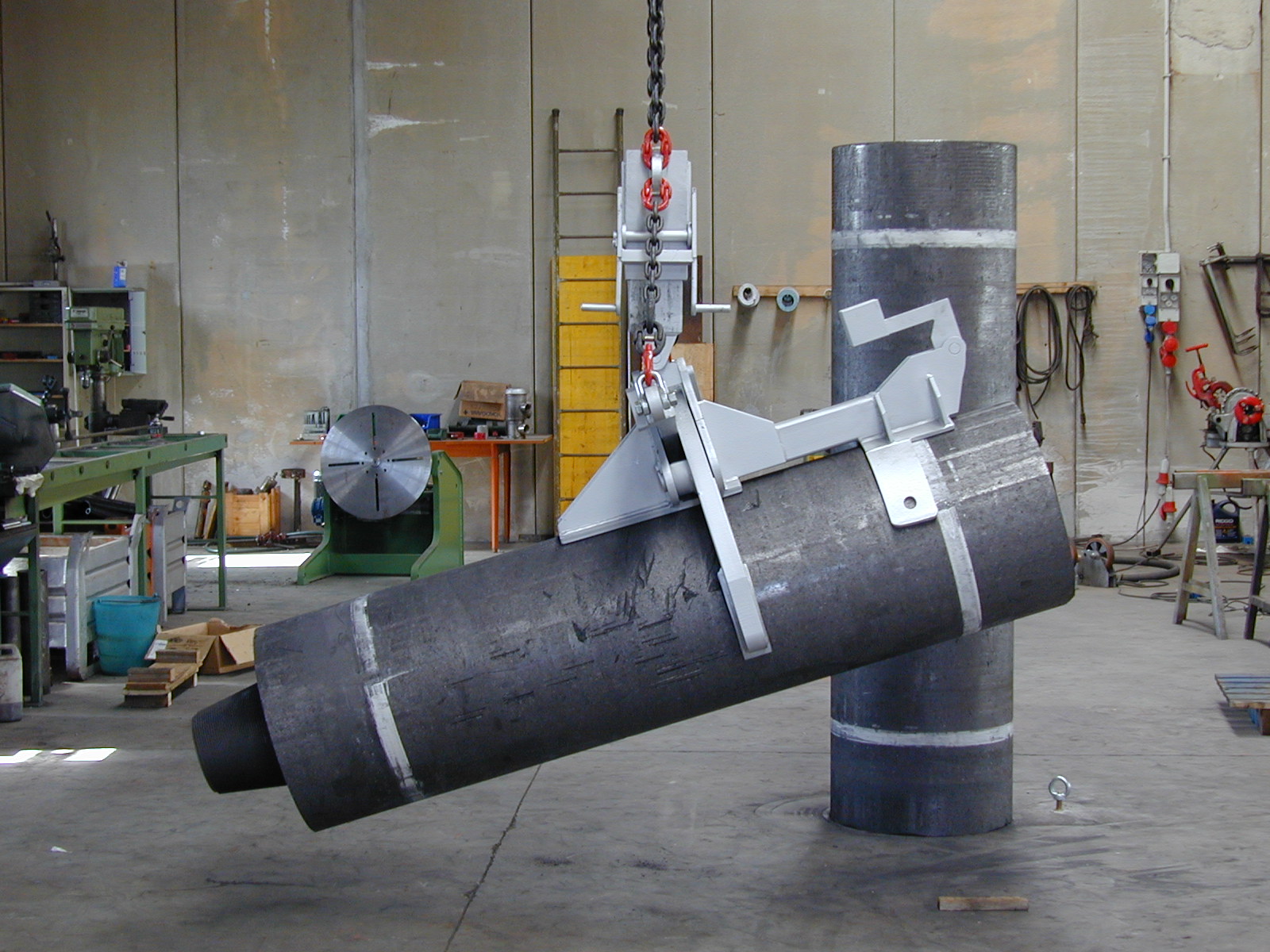

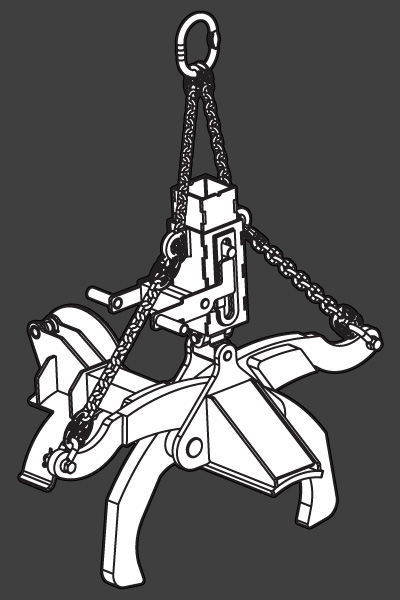

BROKEN ELECTRODE LIFTING DEVICE

- Designed for Electric Arc or Ladle Refining Furnaces.

- Precision clamping of broken electrode for quick removal from furnace.

- Provided by two arms moving like scissors, it is latched open during approach to the element to be removed and automatically un-latches when positioned above electrode. In this way the operation can be done safely e remotely.